Submit a Ticket

About our team

First-line Customer Support, complaints, questions, suggestions, etc.

Frequently Asked Question (FAQ)

If none of the FAQs below solve your problem, please submit a ticket using the form above.

- Yes. The TPU (rubber) cover is mandatory. It must be put on the ILK. It is for the safety of the user. It prevents piching hazard (fingers). It also prevents pants being jammed in the exposed gear behind. It protects the device from ingresssion of sand and water. It also reduces the noise a bit.

- If the TPU cover makes plop sound, very likely it is caused by the hardness of material. During production there is some inconsistency in hardness of the material. Please keep on using it for a day, the sound should be gone after some hundreds of cycles. Make sure that silicone oil is put inside of the cover, so that the Cover can move frictionlessly over the metal surfaces.

- Make sure silicone oil is used on the inner surface of the Cover. Make sure the pants that the patient is wearing is not too tight. Otherwise the pant will push the back of the cover (the bellow part) inwards, making it buckle and touching the exposed gear.

It depends on the prosthetic foot. If the prosthetic foot manufacturer specify the alignment differently, please follow the instruction of prosthetic foot.

And obviously it also depends on the shoe, esp. the heel height, you can imagine if someone is going to wear high-heels, the distance needs to be adapted(reduced, very likely).

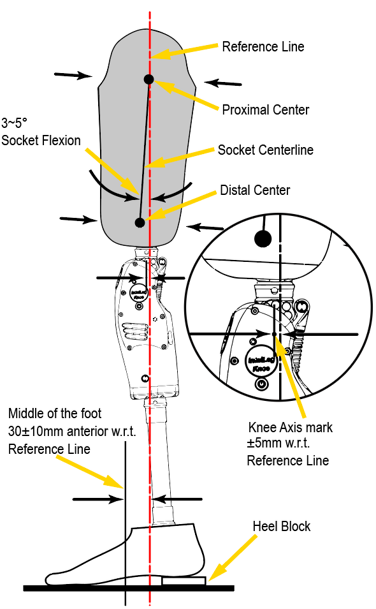

No. The alignment differs from the alignment of C-Leg in the following points:

- Preflexion: ILK does not have a physical preflexion of 4 deg, C-Leg does have it. When performing bench alignment, we require to lock the knee (the knee is straight, no preflexion). The leg assembly of ILK should be straighter than that of C-Leg. When mounting the socket anchor to the top of ILK, normally neutral placement is recommended, no extra preflexion.

- Heel block: by default when doing bench alignment, we recommend putting the shoe of the patient directly on, no heel block is needed. When a shoe is not available, insert a 5mm (any other height deemed necessary) heel bock to compensate for the missing heel of a shoe. NOTE: don't insert a heel block when the shoe is available.

Check socket alignment, foot alignment first (likely increasing plantarflexion can help).

Check if loadcell calibration or stand position calibration is done.

Ask patient to walk with equal step length. Load ILK, check foot rollover. You can check this by looking at the graphs page, if the patient is loading the prosthetic leg properly (think about the human biomechanics).

“Stance resistance“ affect resistance during walking, stair descent and ramp descent.

Extension timing: higher value: extends faster

Loadcell sensitivity: higher value, more sensitive, easier to trigger swing when walking.

Calibrate loadcell first.

Watch the “axial force“ on Graphs page by lifting the foot off from the ground, see if the force reading deviate from 0 by more than 25N.

Ask the patient to put full body weight on the prosthesis see if the axial force is far off from the body weight in Newton (multiply the body weight by 10).

Check if there is sudden change in the plot of “Axial force“ when increase or decrease the loading gradualy.

If any of above happens, the force sensor might be defective.

Upload the diagonistic data and File an ticket immediately https://web.rbionics.com/helpdesk.

Yes. Sometimes it does. Training, suffcient training is always the key. Getting used to an active device take some practice.

Make sure patient don’t panic, fall is caused by the panicing.

We will look to software solutions to reduce the chance.